How to test if a battery has long cycle performance?

Understanding Long Cycle Performance: Definition and Key Metrics

What Is Long Cycle Life in Lithium-Ion Batteries?

The term long cycle life basically describes how well a battery holds onto its usable power after going through hundreds of charge and discharge cycles. When talking about lithium ion batteries specifically, we're looking at how many full charges (from around 80 to 100%) it can handle before dropping down to just 80% of what it originally held - which most folks in the business consider the point where the battery starts becoming too unreliable (Ponemon Institute reported this in 2023). Getting good performance from these cycles matters a lot for things that need lasting power without frequent replacements. Think electric cars that keep running mile after mile, or those massive battery banks used for storing renewable energy across entire power grids.

The Relationship Between Charge-Discharge Cycles and Capacity Retention

Every time batteries go through charging and discharging, they slowly lose their ability to hold power because of chemical changes happening inside the electrodes and electrolyte materials. When we push them harder by draining deeper each cycle, this wear happens much quicker. Take a look at real world numbers: batteries cycled down to 90% of their capacity typically reach their end point around 40% sooner compared to those only drained to 50%. Finding the right balance between how deeply we discharge and how long our batteries last becomes really important for anyone wanting maximum performance over time.

Industry Standard: 80% Capacity as the End-of-Life Threshold

The 80% capacity benchmark—where a battery retains only four-fifths of its initial energy—is widely accepted as the functional endpoint across industries. Research shows that performance and reliability decline sharply below this level, with failure rates increasing fivefold (IEEE 2023). This standard informs warranty terms, maintenance schedules, and replacement planning.

Standardized Testing Methods for Evaluating Long Cycle Performance

Overview of Battery Cycle Life Testing Protocols

The IEC 61960 standard offers methods to evaluate how batteries perform over many cycles using controlled tests where they get charged and discharged repeatedly. Labs run these tests faster than normal by speeding up the aging process, which lets them see what happens after years of use in just a few weeks. When facilities follow the EN 45552:2020 guidelines for durability testing, their predictions about battery lifespan tend to be pretty accurate most of the time, usually within around 2% error margin. This shows why sticking to established standards matters so much for getting reliable data when testing battery longevity.

Charge-Discharge Cycling: CC-CV and Constant Current Methods

Two primary methods are used in cycle testing:

- Constant Current-Constant Voltage (CC-CV): Applies steady current until reaching a voltage limit, then holds voltage constant to complete charging. This method balances efficiency and cell health.

- Pure Constant Current: Simpler but can overstress cells by ignoring voltage limits.

Studies show CC-CV improves cycle life by 18% compared to constant current alone when testing to 80% capacity retention.

Monitoring Voltage, Current, and Internal Resistance During Testing

Real-time monitoring of key parameters enables early detection of degradation patterns. Critical metrics include:

| Parameter | Measurement Frequency | Critical Threshold |

|---|---|---|

| Voltage | Every 5 seconds | ±5% from nominal |

| Internal Resistance | Each cycle | 20% increase |

Automated systems apply ASTM F3283-17 standards to flag anomalies and identify capacity fade trends during extended testing.

Lab vs. Real-World Conditions: Addressing Simulation Discrepancies

Lab tests generally happen in controlled settings around 25 degrees Celsius give or take a degree, but out there in the real world, batteries face all sorts of temperature changes and varying workloads. Just think about how much faster battery life drops when exposed to extreme heat or cold. According to research published by AAC in 2023, these temperature swings alone can speed up battery wear by as much as 35%. The good news is that modern testing methods are getting smarter. Many facilities now use climate control rooms ranging from minus 20 down to plus 60 degrees Celsius along with actual usage patterns rather than just theoretical models. This approach cuts down on inaccurate simulations significantly, bringing error rates down from roughly 40% to below 12% in most cases.

Essential Equipment for Accurate Long Cycle Testing

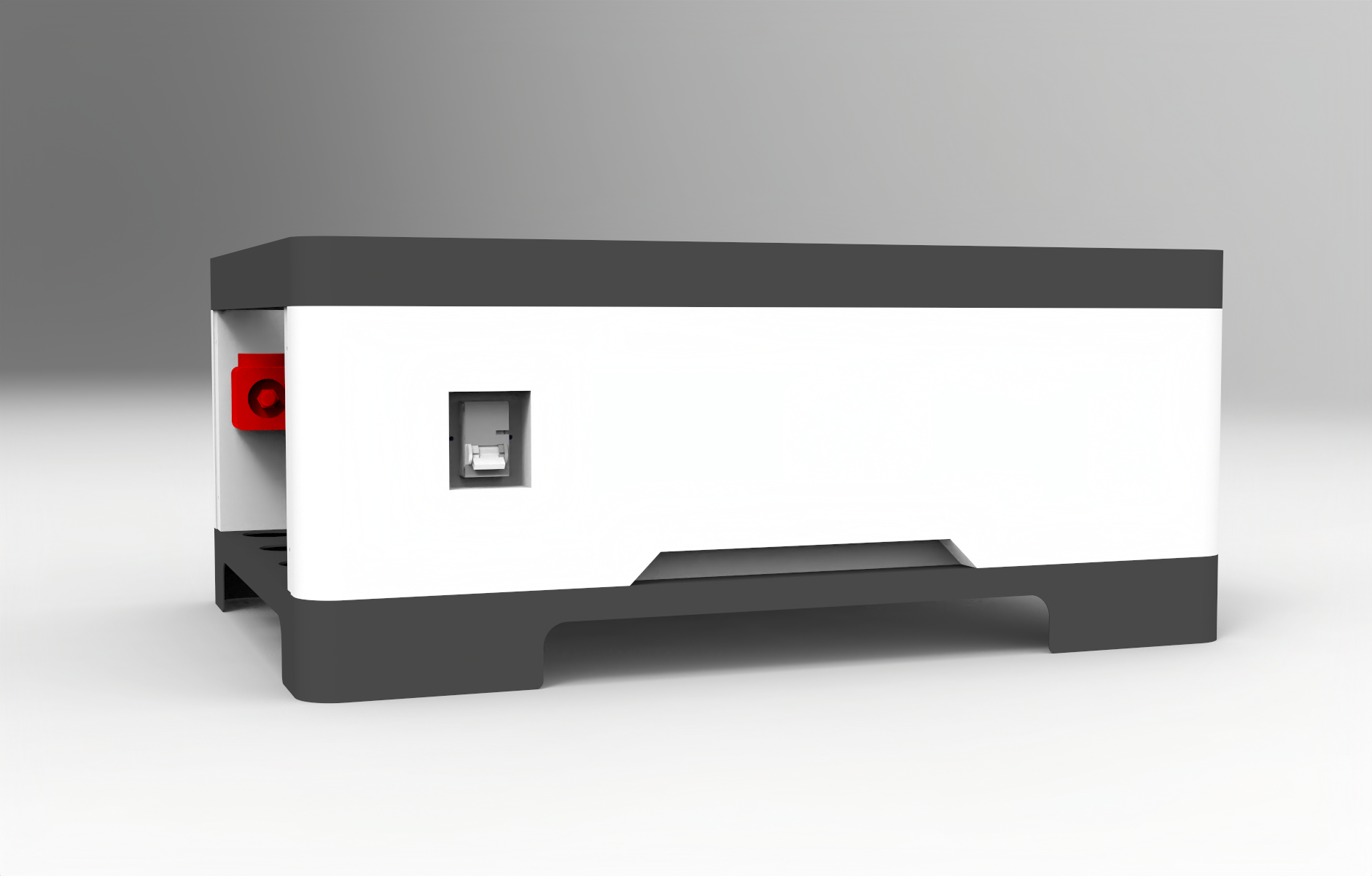

Battery Cyclers: Features and Selection Criteria

Battery cyclers are central to long cycle testing, enabling precise replication of charge-discharge sequences. High-end models offer ±0.05% current accuracy and programmable environmental control, as validated in the BTS-4000 study. Key selection factors include:

- Multi-channel capability for parallel testing

- Operational temperature range of -40°C to +85°C

- Compliance with UN 38.3 and IEC 62133 safety standards

These features ensure reliable, scalable evaluation of lithium-ion battery longevity.

Data Acquisition Systems for Continuous Performance Monitoring

Modern data acquisition (DAQ) systems monitor over 15 parameters simultaneously, including impedance (down to 0.1mΩ resolution) and entropy coefficients. Integrating thermal profiling tools reduces capacity fade prediction errors by 22% compared to voltage-only monitoring. Essential capabilities include:

- 24-bit ADCs for high-precision microvolt measurements

- Sampling rates exceeding 1kHz to capture transient events

- Cloud-based analytics for real-time degradation tracking

Together with battery cyclers, DAQ systems enable comprehensive assessment of energy density (Wh/kg) and power retention (%) over thousands of cycles.

Assessing Degradation and State of Health (SOH) Over Long Cycle Life

Effective evaluation of long cycle performance relies on systematic monitoring of degradation and advanced modeling of State of Health (SOH).

Tracking Capacity Fade to 80% Over Extended Charge-Discharge Cycles

Most lithium ion batteries tend to drop around 1-4% of their capacity every year when used normally, though frequent charging cycles really speed things up. Labs run standard tests where they check how much energy comes out after each full charge/discharge cycle, plotting these results on graphs that show just how temperature changes and depth of discharge affect battery lifespan. Industry folks generally agree that once a battery hits about 80% of its original capacity, it's time to think about replacing it for most everyday uses, even though some specialized equipment might still work beyond that threshold.

State of Health Estimation Using Cycle Life Models

SOH models today are getting pretty advanced by mixing real world cycling data with electrochemical principles to predict how long a battery will last before needing replacement. Some newer hybrid approaches that bring together machine learning techniques with actual physical wear patterns have managed to get capacity predictions within just under 3% accuracy even after 500 charge cycles. What makes these models work so well is their ability to look at things like voltage fluctuations over time, increasing internal resistance, and temperature changes during operation, which allows them to make educated guesses about battery capacity without requiring constant full recalibration.

Case Study: SOH Prediction in EV Batteries After 1,000+ Cycles

In automotive applications, early-cycle data proves highly predictive of long-term performance. A 2024 study found that using the first 200 cycles allowed accurate forecasts of capacity at 1,000 cycles, with prediction errors below 5%. This highlights the value of continuous monitoring and data-driven modeling in ensuring reliability in high-demand environments.

Key Factors Influencing Long Cycle Performance

Temperature Effects on Battery Aging and Cycle Life

Temperature significantly impacts degradation rates, following the Arrhenius relationship. Batteries cycled at 45°C degrade 2.3 times faster than those at 25°C (Battery Aging Study 2023), primarily due to accelerated electrolyte breakdown and solid electrolyte interphase (SEI) layer growth. Maintaining optimal thermal conditions is critical for maximizing cycle life.

Impact of Charge/Discharge Rates and Depth of Discharge (DoD)

High charge/discharge rates (>1C) induce mechanical stress that damages electrode structures, while deep discharges (>80% DoD) deplete active lithium. Field data shows a clear inverse relationship between DoD and cycle life:

| DoD Level | Cycle Life (to 80% SOH) |

|---|---|

| 100% | 500 cycles |

| 50% | 1,200 cycles |

Limiting DoD to below 60% can double lifespan in stationary storage systems.

Balancing High Performance and Long Cycle Life in Industry Applications

The electric vehicle market shows us the classic balancing act between how well they perform versus how long they last. When drivers hit the brakes hard, the regen system charges faster but can actually cause cracks in the battery anodes over time. And those long highway trips at high speeds (around 4 times normal discharge rates) wear down batteries much quicker than stop-and-go city driving does, making them degrade about 18% faster. Some folks might wonder why companies spend extra money on thermal management systems that bump up costs by around 9 to 12%. Well, these systems keep batteries cooler during operation and somehow manage to stretch their lifespan by as much as 40%. Big car makers are getting smart about this too. They're implementing machine learning algorithms to fine tune when and how batteries get charged. These smart charging methods cut down on calendar aging by roughly 22%, all while still maintaining good power output for commercial storage applications across different industries.

FAQ

What is the importance of long cycle life in lithium-ion batteries?

Long cycle life determines how effectively a battery can retain usable power over extensive charge-discharge cycles, crucial for applications requiring durable power sources like electric vehicles and large energy storage systems.

How does temperature affect battery life?

Temperature impacts degradation rates significantly. Batteries degrade faster in extreme temperatures, which can accelerate the wear process, hence maintaining optimal thermal conditions is crucial for maximizing cycle life.

What is considered as the end-of-life threshold for a battery?

The end-of-life threshold is typically when a battery retains only 80% of its original capacity, at which performance and reliability can decline sharply.