How safe is low voltage energy storage system in home use?

Understanding Low Voltage Safety Realities for Home ESS

Why 'Low Voltage' Doesn't Mean 'No Risk': Human Physiology and Fault Current Behavior

Low voltage systems might run under 50 volts AC or 120 volts DC according to NEC guidelines, but don't let those numbers fool anyone about safety. Our bodies react surprisingly strongly to electricity even at small levels. Just 5 milliamps flowing through skin can lock muscles up so someone gets stuck grabbing a live wire. And when it hits around 50 milliamps? That's enough to mess with heart rhythms badly. These problems happen mostly when something goes wrong with the system. Think about what happens if insulation fails or there's a ground fault on surfaces like damp concrete floors or metal workbenches. Suddenly, even a 48 volt DC setup becomes risky because contact resistance drops to dangerously low levels around 480 ohms, letting 100 milliamps flow freely. Then there's the heat factor nobody expects. Arc flashes in these lower voltage setups can spike temperatures past 3,500 degrees Celsius in an instant, setting fire to anything nearby. So forget what people think about voltage categories. Good insulation practices, proper grounding techniques, and fast response to faults aren't just recommendations for electricians working with these systems. They're absolute necessities regardless of whether the power supply meets traditional definitions of high voltage or not.

Voltage Thresholds in Residential Context: 48V DC as the Practical Benchmark for Low Voltage ESS

Residential energy storage increasingly adopts 48V DC as the safety benchmark, balancing power density with inherently lower risk. This voltage sits beneath the 60V DC threshold where international standards like IEC 61140 require enhanced protective measures. Compared to higher-voltage alternatives, 48V systems deliver measurable safety advantages:

| Safety Factor | 48V DC Advantage |

|---|---|

| Shock Risk | Remains below the sustained let-go threshold (<50mA under typical dry-skin conditions) |

| Arc Flash Energy | Generates ~80% less incident energy than equivalent 120V systems, reducing burn severity and ignition potential |

| Insulation Requirements | Allows use of thinner, more cost-effective dielectric materials without compromising protection |

The NEC Class 2 circuit designation further supports this approach by capping output at 100W-limiting available fault energy and enabling safer DIY-friendly installations while still meeting core home backup needs.

Thermal Runaway and Fire Safety in Low Voltage Residential Batteries

Chemistry Matters: LiFePO„¢ vs. NMC Thermal Stability Under Abuse Conditions (UL 9540A)

The chemistry behind batteries plays a big role in how safe they are when installed in homes with low voltage energy storage systems. Lithium iron phosphate, or LiFePO4 as it's often called, doesn't get into thermal runaway situations because of its stable olivine crystal structure. These batteries can actually hold up pretty well even when temperatures go past 260 degrees Celsius, which is around 500 Fahrenheit. On the flip side, nickel manganese cobalt cells tend to break down violently once they hit about 200 degrees Celsius. When things go wrong, these NMC cells can reach scorching temperatures over 900 degrees Celsius, sometimes hitting 1,652 Fahrenheit in worst case scenarios. Tests under UL 9540A standards back this up showing that LiFePO4 cells usually just fail where they are without spreading problems elsewhere. But NMC modules have issues propagating through the system in about 8 out of 10 cases during testing. Since most home installations use passive cooling methods and have limited space, the inherent stability of LiFePO4 makes it the better choice for low voltage ESS applications. This means homeowners don't need complicated active thermal management systems to keep things running safely.

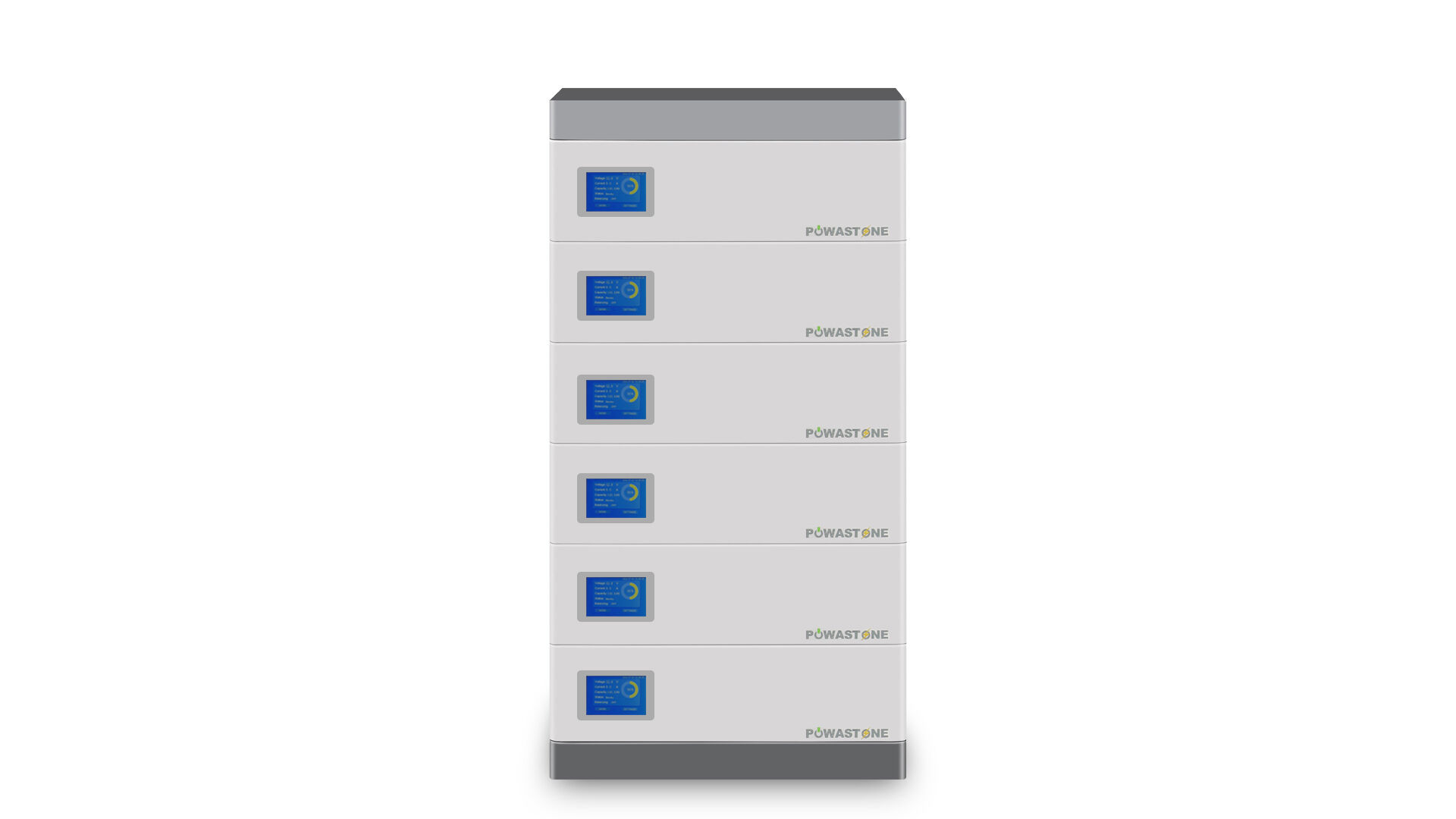

Enclosure Design and Propagation Control in Compact Low Voltage Systems

Good enclosure design matters a lot when it comes to containing failures in those small residential energy storage systems. Modern multi-layer designs typically include ceramic thermal barriers along with pressure activated venting channels that help handle combustion byproducts properly. If things get too hot inside or pressure builds up beyond safe levels, special flame arresting vents send those hot gases down away from other parts of the system. At the same time, intumescent seals start expanding to create barriers around any damaged modules. Tests have actually shown that with these features in place, fires tend to spread to less than 5% of nearby cells during thermal incidents. Combine this with ongoing temperature checks throughout different cell groups and we're looking at an engineering solution that keeps problems isolated within UL certified safety limits. This works even in cramped areas where these systems are often installed, like utility rooms or garage corners.

Critical Safety Features: BMS, Monitoring, and Early Failure Detection

Beyond Voltage: Detecting Swelling, Corrosion, and Connection Faults in Low Voltage ESS

Looking at voltage levels alone just isn't enough when it comes to safety in low voltage energy storage systems. What really matters happens physically first, long before any electrical problems show up on the meter. Take cell swelling for instance. When cells start expanding, that means there's gas building up inside plus mechanical stress developing, which could lead to ruptures if left unchecked. Modern systems now combine force sensitive sensors with careful voltage monitoring to catch these issues early on. Another big concern? Corrosion at connection points. This creates higher resistance between components, leading to hot spots that might not set off regular voltage alarms but still pose serious fire hazards to nearby materials. And don't forget about those loose connections either. They create tiny arcs that generate sudden heat spikes right before things go completely wrong. The latest battery management systems actually spot all these problems through advanced techniques like thermal mapping across multiple points and something called impedance spectroscopy. These systems can detect even minor resistance changes around 15%. Why does this matter so much? According to the National Fire Protection Association's 2023 report, nearly a quarter of residential energy storage system failures were traced back to physical degradation issues instead of simple overvoltage or overcurrent problems.

Essential BMS Capabilities for Residential Low Voltage Systems

An effective residential BMS goes far beyond basic voltage regulation. It must provide:

- Real-time multi-parameter tracking, including inter-cell temperature gradients, insulation resistance, current leakage, and state-of-health metrics

- Predictive failure algorithms, trained on historical degradation patterns to forecast end-of-life or thermal stress onset

- Redundant hardware-level cutoffs, capable of isolating faults within milliseconds of detecting abnormal thermal rise or impedance shift

- Cloud-integrated diagnostics, delivering remote alerts and actionable insights via secure IoT protocols

Old school voltage monitors just aren't cutting it anymore compared to modern systems that keep track of what's happening inside batteries at all times. These new setups watch for things like tiny changes in how much resistance there is inside and how heat moves between different parts of the battery pack. The real value comes when problems can be addressed early on. For instance, if the system detects swelling in a cell, it might automatically cut back on power being sent through that area before something bad happens. Most battery failures don't appear out of nowhere either. Industry data shows around 78% develop slowly over time periods ranging from weeks to months. This kind of detailed monitoring completely changes how we approach battery maintenance, moving away from fixing things after they break down to actually anticipating issues before they become serious problems.

Certification, Installation Standards, and Environmental Safeguards

Getting proper certifications and following installation rules are really important when deploying low voltage energy storage systems safely. Independent certifications like UL 9540 for system safety, UL 1973 for cell performance, and NFPA 855 regarding fire protection give designers third party proof that their systems can handle faults without failing. When installing these systems, electricians need to stick to local regulations too. In North America, they follow NEC Article 706 while elsewhere around the world IEC 62477 applies. These standards require using approved parts, trained workers, and various tests after installation including checking insulation resistance, making sure there's enough space for ventilation, and verifying enclosures are intact. Looking at the bigger picture, manufacturers should care about what happens to their products long term. Companies aligned with ISO 14001 standards make greener products and have programs for recycling old units properly. According to recent industry stats from last year, about three quarters of all safety problems after service happen because people dispose of these systems incorrectly. That's why managing how these systems enter, operate, and eventually exit the market needs to be part of any safety plan from day one.

FAQ

What is considered low voltage in home energy storage systems?

Low voltage in home energy storage systems typically refers to those operating under 50 volts AC or 120 volts DC, following NEC guidelines.

Why is 48V DC commonly chosen for residential energy storage systems?

48V DC is commonly chosen as it offers a balance between power density and safety. It significantly reduces shock risk and arc flash energy compared to higher-voltage systems.

How does battery chemistry affect thermal runaway and fire safety?

Batteries like LiFePO4 are less prone to thermal runaway due to their stable structure compared to NMC cells, which can become dangerously hot under thermal stress.

What role does a Battery Management System (BMS) play in safety?

A BMS is crucial for monitoring multiple parameters, detecting early failures, and ensuring safe operation by isolating faults quickly.